IDN Work Management System

IDN Software is the Ideal Solution for Facility Managers

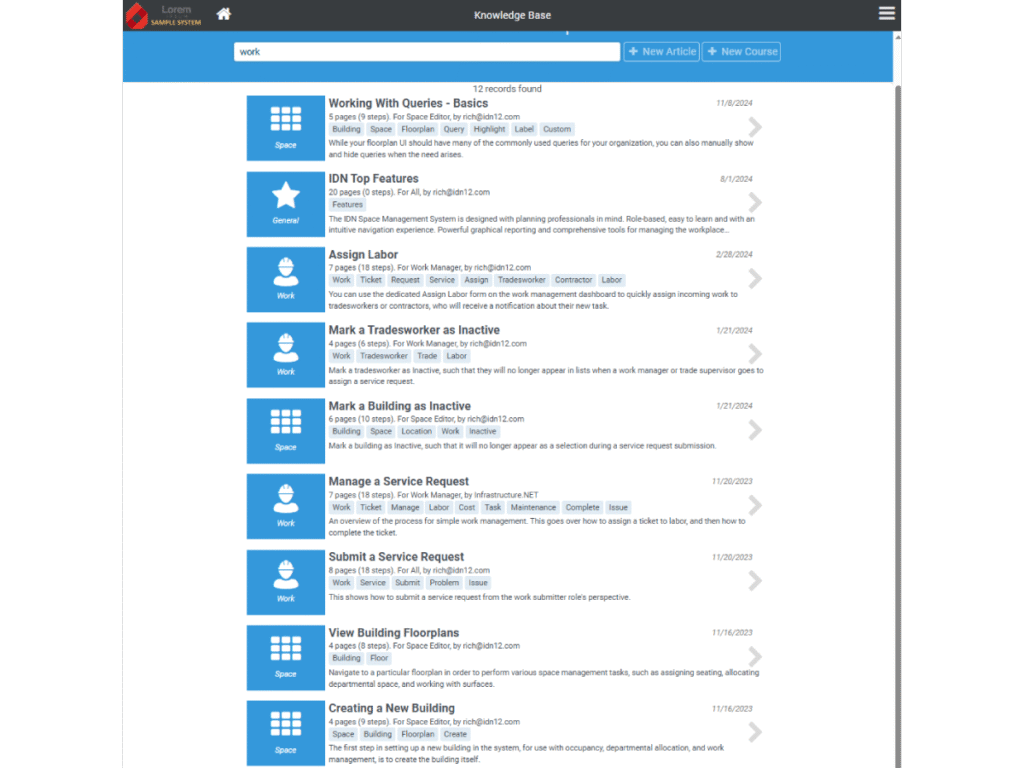

Let’s review the key features, functionalities, and concepts in the IDN Work Management System. The focus is on understanding the system’s capabilities for managing work requests, assignments, completion, and preventative maintenance within a facilities management context.

Tools for Your Facility Management Needs

Optimize & Fully Utilize Your Facilities

Main Themes

Comprehensive Work Management

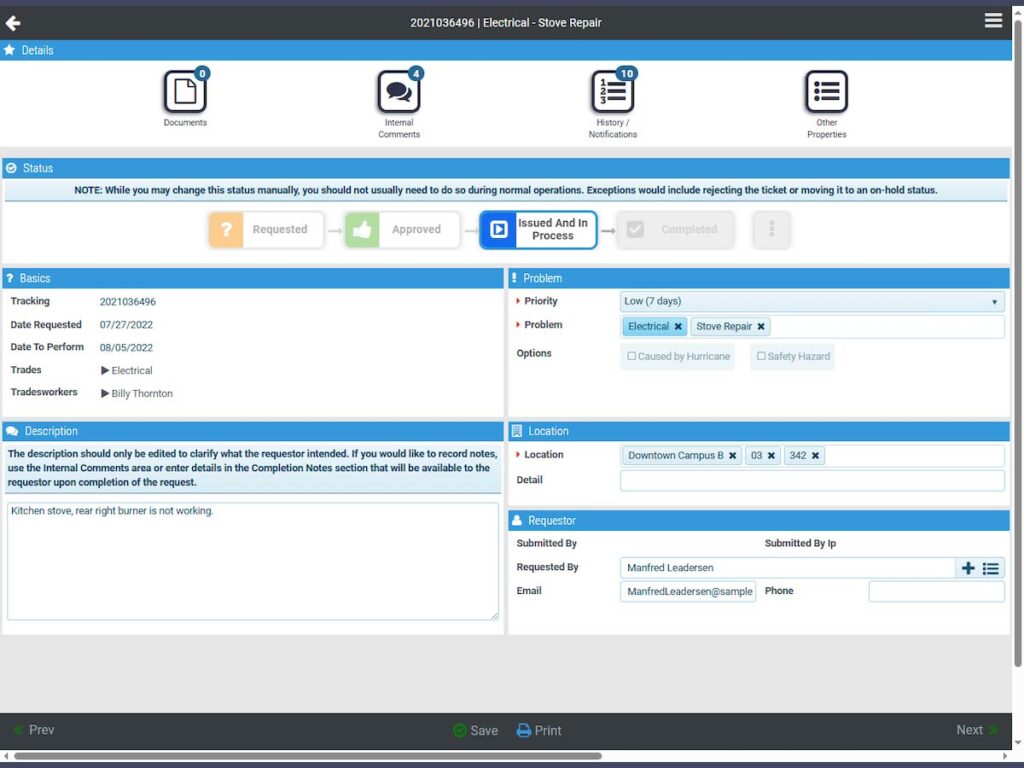

The IDN system provides a centralized platform for managing a wide range of facility-related issues, referred to as “service requests,” “work orders,” or “tickets.” These can range from basic repairs (e.g., plumbing, lighting) to more complex tasks (e.g., repainting, mechanical repair, grounds maintenance).

Workflow-Driven Process

The system enforces a structured workflow for managing these requests, from initial submission through review, assignment, execution, completion, and closure. This workflow involves different user roles with varying levels of access and responsibilities.

Role-Based Access and Dashboards

The user interface is tailored to different roles, such as administrators, trade supervisors, and trades workers, each with specific dashboards displaying relevant information and functionalities. Administrators have access to “basically everything,” while lower-rights users see interfaces relevant to their tasks.

Customizable and Flexible

The system appears highly customizable, allowing for the configuration of problem categories, priorities, assignment rules, notification settings, form fields, and even the workflow process itself to align with an organization’s specific needs.

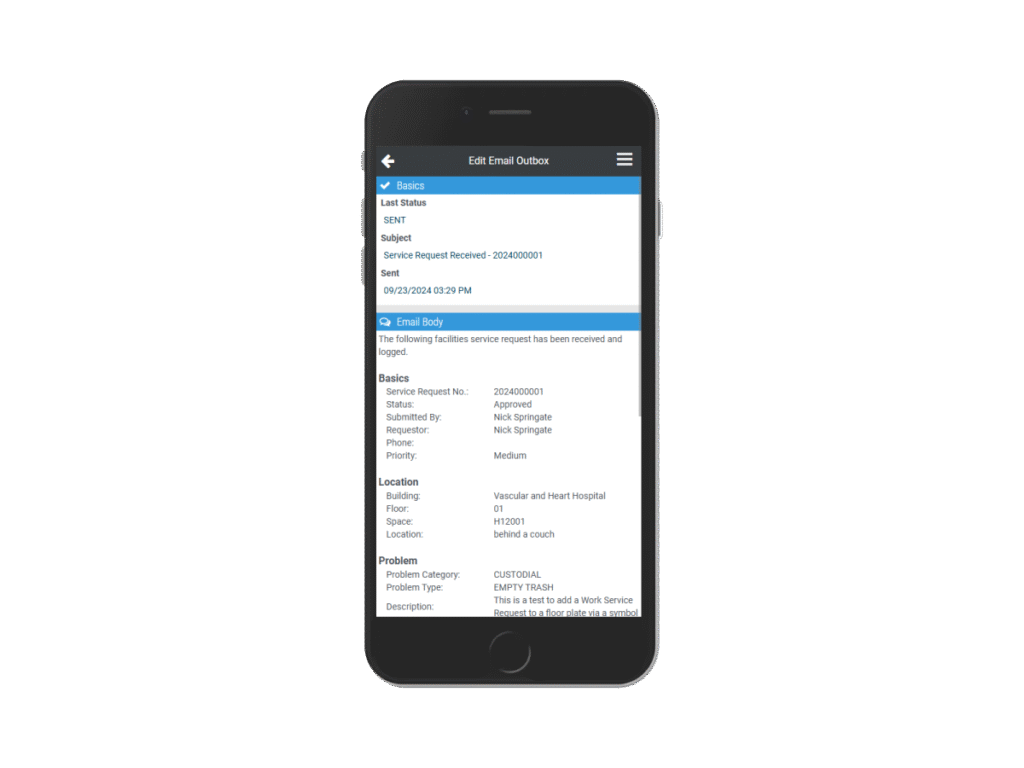

Mobile Accessibility

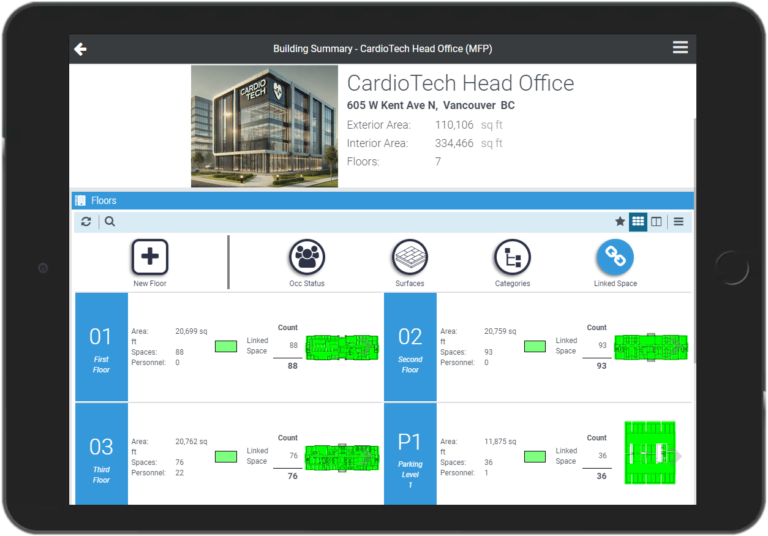

The system emphasizes accessibility across different devices, including phones and tablets, ensuring that users can submit requests and manage work from various locations. While complex features like floor plan management are better suited for larger screens, basic functionalities are mobile-friendly.

Integration of Information

The system integrates key information such as requester details, problem description, location (including floor plans), attachments (photos, documents and videos), assigned personnel, work progress, hours, costs, and completion details within each ticket.

Preventative Maintenance (PM) Capabilities

The system includes a robust preventative maintenance module for scheduling and managing routine maintenance tasks on equipment and locations. This involves defining equipment, reusable procedures, and schedules, with options for recurrence patterns, pre-assignment, and linking to relevant documentation.

Comprehensive Work Management:

The IDN system provides a centralized platform for managing a wide range of facility-related issues, referred to as “service requests,” “work orders,” or “tickets.” These can range from basic repairs (e.g., plumbing, lighting) to more complex tasks (e.g., repainting, mechanical repair, grounds maintenance).

Workflow-Driven Process:

The system enforces a structured workflow for managing these requests, from initial submission through review, assignment, execution, completion, and closure. This workflow involves different user roles with varying levels of access and responsibilities.

Role-Based Access and Dashboards:

The user interface is tailored to different roles, such as administrators, trade supervisors, and trades workers, each with specific dashboards displaying relevant information and functionalities. Administrators have access to “basically everything,” while lower-rights users see interfaces relevant to their tasks.

Customizable and Flexible:

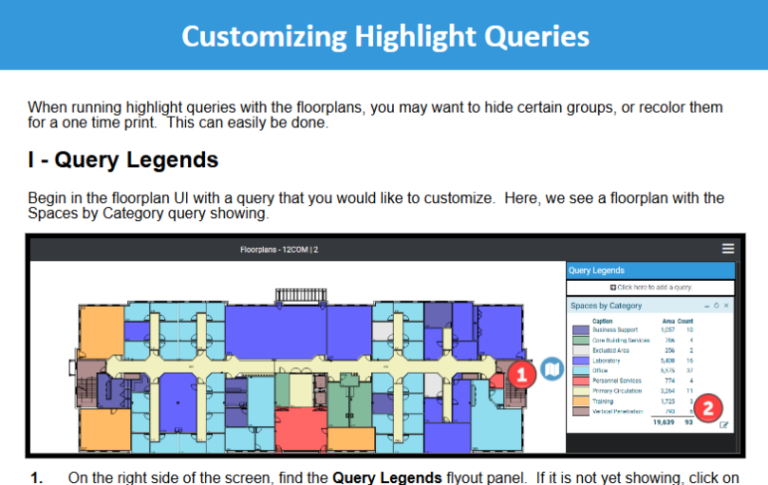

The system appears highly customizable, allowing for the configuration of problem categories, priorities, assignment rules, notification settings, form fields, and even the workflow process itself to align with an organization’s specific needs.

Mobile Accessibility:

The system emphasizes accessibility across different devices, including phones and tablets, ensuring that users can submit requests and manage work from various locations. While complex features like floor plan management are better suited for larger screens, basic functionalities are mobile-friendly.

Integration of Information:

The system integrates key information such as requester details, problem description, location (including floor plans), attachments (photos, documents and videos), assigned personnel, work progress, hours, costs, and completion details within each ticket.

Preventative Maintenance (PM) Capabilities:

The system includes a robust preventative maintenance module for scheduling and managing routine maintenance tasks on equipment and locations. This involves defining equipment, reusable procedures, and schedules, with options for recurrence patterns, pre-assignment, and linking to relevant documentation.

Reporting and Analytics:

The system offers various reporting capabilities to track key metrics such as completed work, costs, open requests, and user activity, providing insights into facility management operations. These reports can be customized and scheduled for automated delivery.

Most Important Ideas and Facts

1. Work Request Submission

Users can submit service requests through customizable web forms accessible on various devices.

Forms include fields for problem description, location (with optional floor plan integration), priority, and attachments.

All of these forms, even the complicated floor plan interface, are all usable from different devices.

Problem categories and types are customizable through “background data,” allowing organizations to tailor the system to their specific needs.

Rules can be set up to trigger specific actions (e.g., email notifications) based on the type of problem reported (e.g., “safety hazard”).

3. Assignment and Notifications

Assignment rules can automate the routing of tickets based on criteria like building or equipment to specific trades or teams.

Automated notifications are sent to relevant parties at each stage of the workflow, such as when a request is received, assigned, completed, or put on hold.

The requester receives notifications about the status of their request, including completion and any closing comments.

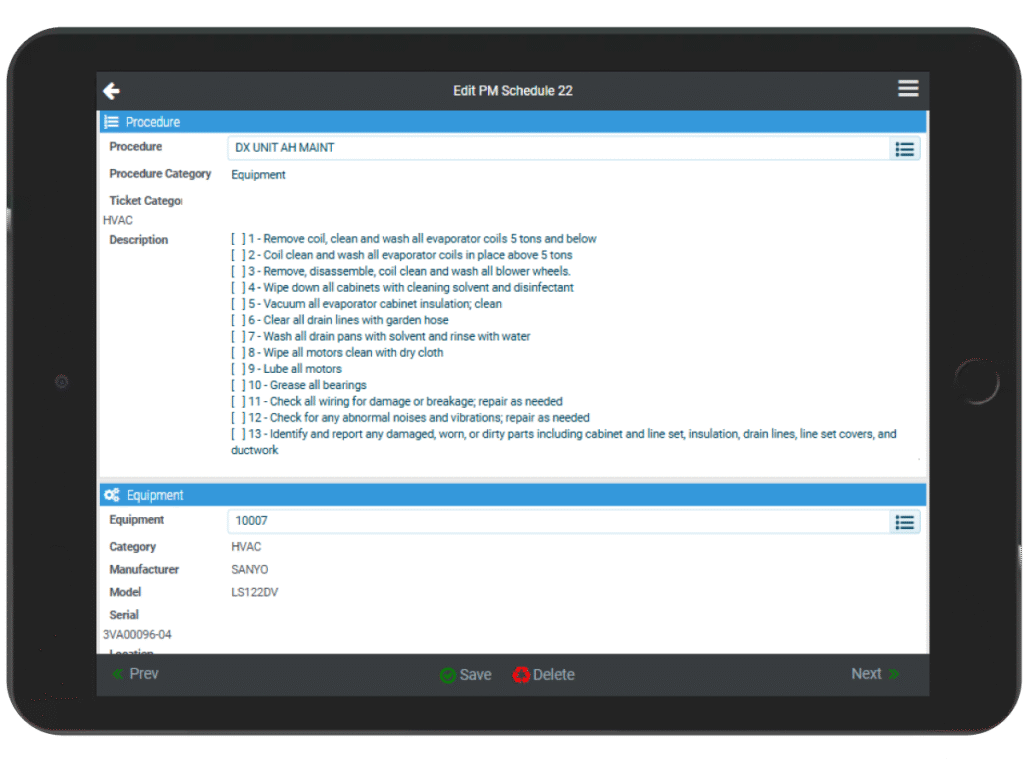

5. Preventative Maintenance (PM)

PM involves defining equipment, creating reusable maintenance procedures with detailed steps, and establishing schedules for these procedures.

Schedules can be recurring (e.g., monthly, quarterly) with customizable recurrence patterns.

PM schedules can be pre-assigned to specific trades workers or contractors.

The system can generate work orders automatically based on the defined PM schedules.

A calendar view provides a visual representation of upcoming PM tasks.

Every PM entry is a unique combination of the Equipment plus the procedure.

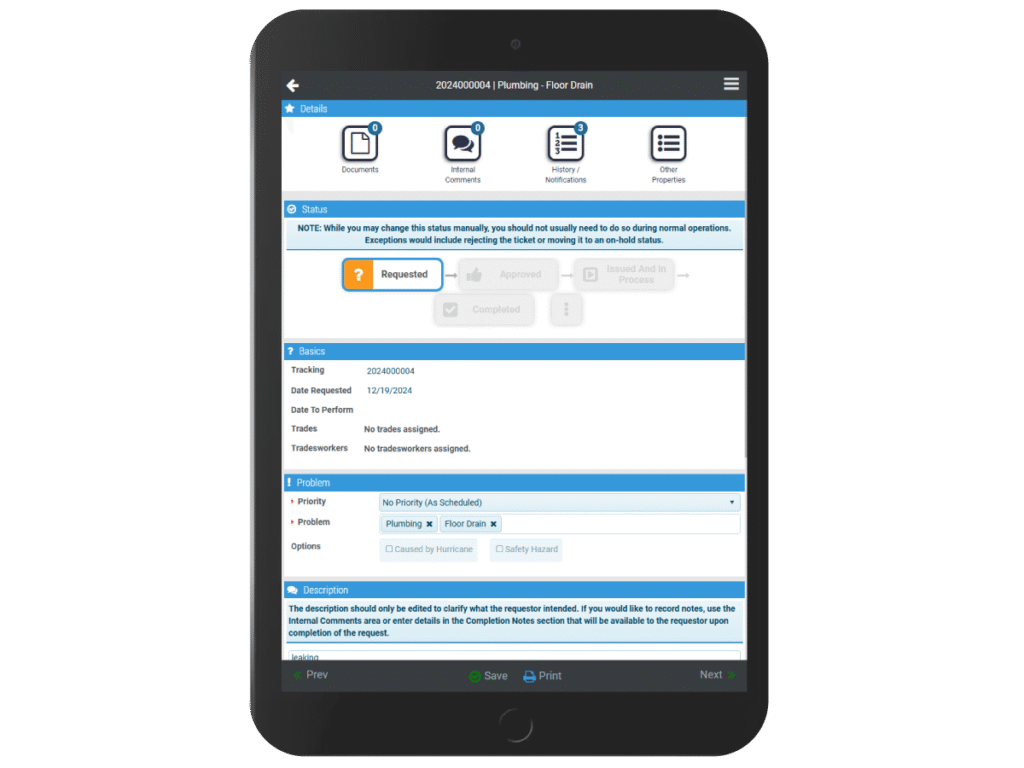

2. Workflow and Roles

The typical workflow involves request submission, review/approval by management, assignment to a trade supervisor, delegation to a trade worker or contractor, task completion with input of hours/costs/comments, supervisor review, and final closure.

The workflow shows the progress of a work request along the status chain.

Different user roles (administrator, trade supervisor, trades worker) have distinct dashboards and functionalities.

Trade supervisors can manage their team’s workload, assign tasks, and review completed work.

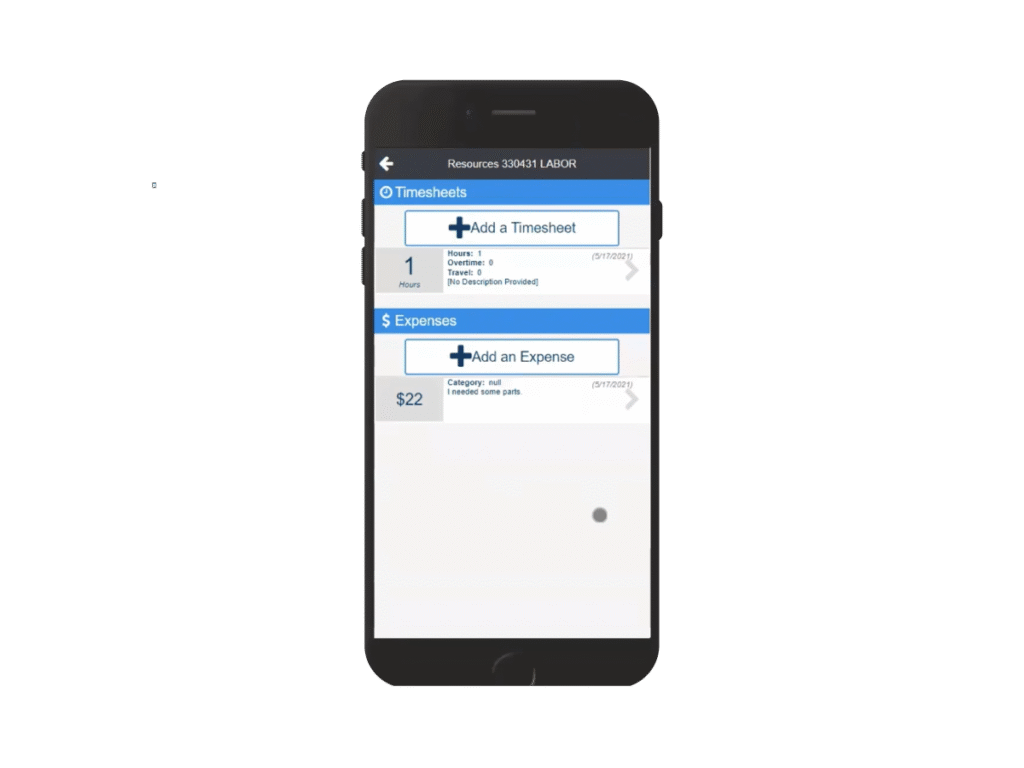

Trades workers can access their assigned tasks, update progress, add hours and costs (if enabled), and mark work as complete via their interface (including a simulated mobile view).

Contractor workflows can be handled in different ways, including providing them with trades worker-like access, using email with simple completion buttons, or relying on the trade supervisor to update their status.

4. Task Completion and Details

Trades workers can record time spent (including overtime) and any associated costs (e.g., parts).

Attachments, such as photos of completed work, can be required or optional.

Internal comments can be added to tickets for communication among the maintenance team.

Trade supervisors review completed work and can add additional information or closing comments.

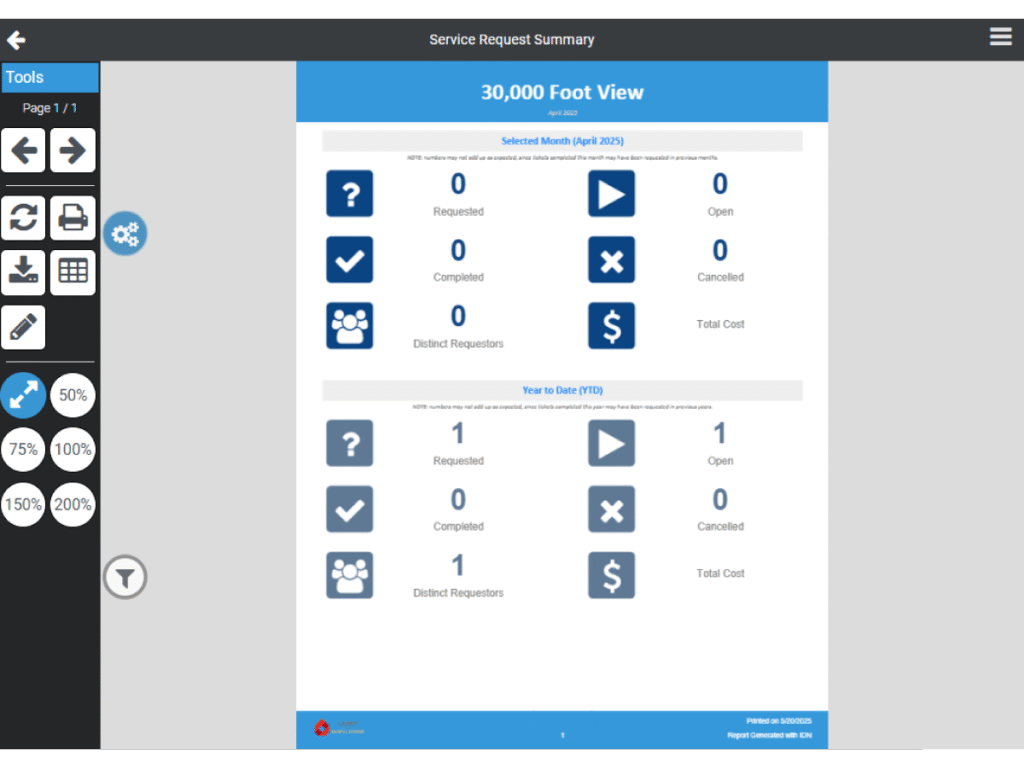

6. Reporting

The system offers various standard reports on completions, costs, open requests, and other key metrics, broken down by different criteria (e.g., building, trade).

Reports can be customized and combined into comprehensive summaries.

Reports can be scheduled for automated email delivery to stakeholders who may not be direct system users.

Example reports include “completions and costs” across a fiscal year, showing trends by building.

7. Customization and Simplicity

The system emphasizes the ability to customize various aspects to match an organization’s specific work processes.

The goal is to provide a “comprehensive system” that is still “simple” to use by streamlining forms and eliminating unnecessary steps.

User help documentation is available within the system and as downloadable PDFs.

Conclusion

The IDN Work Management system is a robust and flexible platform designed to streamline and manage facilities maintenance operations. Its key strengths lie in its customizable workflow, role-based access, mobile capabilities, integration of relevant information, comprehensive preventative maintenance module, and reporting features.

The system aims to improve efficiency and communication across different teams and stakeholders involved in the work order process. IDN is happy to schedule discussions that can delve deeper into specific areas like reporting customization, integration with other systems, and detailed configuration options for preventative maintenance.